Technical Specification for R10 When used on a timber suspended floor

Incorporating the latest changes to the Approved Document E, the minimum and maximum airborne noise and impact sound insulation requirement for separating floors are as follows:

| Properties Values | ||

|---|---|---|

| Airborne Sound Reduction DnTw,w+C;tr | Impact Sound Level LnTw | |

| Conversion | 43dB or greater | 64dB or less |

| New Build | 45dB or greater | 62dB or less |

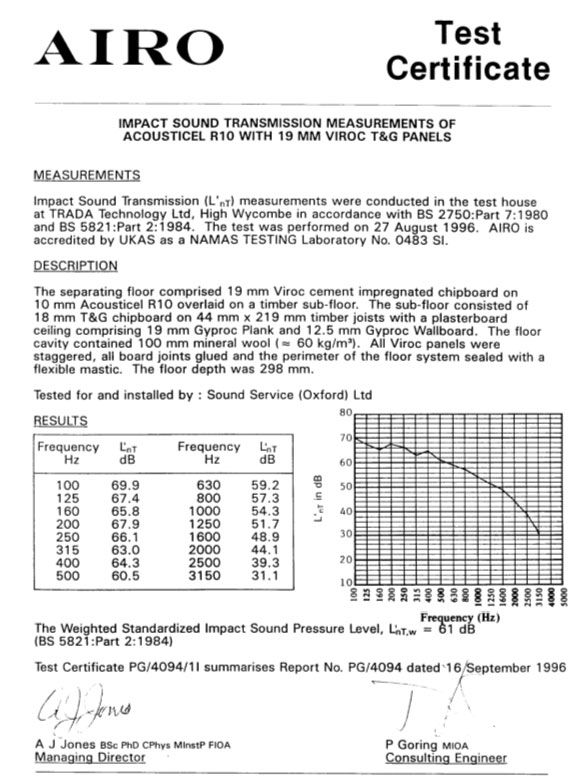

To comply with the requirements of Document E, R10 sound insulated separating floors have been tested in accordance with BSEN ISO 717-1997 and BSEN ISO 717:1997. Substituting the 25mm mineral wool floating layer normally specified with a more stable and efficient recycled rubber resilient layer. 10mm thick sound absorbing Acousticel R10 is installed onto timber suspended floors as detailed above. Note: Existing or new square edged timber floors should be overlaid with our SBM5 before installing the R10 and the ceiling should be supported with our 16mm deep Resilient Bars.

With a floating layer of 19mm thick QUIETBOARD cement impregnated t&g chipboard -placed on top of the R10 acoustic insulation as shown above, the following site test result was recorded:

| Site test result | ||

|---|---|---|

| Airborne DnT,w+Ctr | 48dB | |

| Impact LnTw | 52dB | |

| With R10 and QuietBoard installed on top of a base floor of QuietBoard, the following site test result was recorded: | ||

| Airborne DnT,w+Ctr | 55dB | |

| Impact LnTw | 55dB | |

WHICH MEETS THE NEW CHANGE OF USE, CONVERSION AND NEW BUILD REQUIREMENTS NOTE! Size and spacing of the timber joists will affect the overall sound insulating performance. If the joists differ from those on the floor that was tested, please contact us for further advice.

NOTE: Failure to follow the Application Instructions to the letter may result in a failed test!

See all our other test certificates below.