Sound Proofing a Wall

More information on sound proofing products for walls (party walls) mentioned in this article can be viewed elsewhere on this site by clicking on the relevant hyperlinked text. Sound proofing products can also be purchased on-line or you can phone us on the number on the top left hand corner of this page that is a local call rate. Mobiles can call us on 01993 704981.

Help for Sound proofing Walls

Noise through any wall (party Wall) dividing neighbours can be a problem and more so at night when there is less background noise being generated within the home. Part E of the new Building Regulations have a minimum soundproofing standard for all new flats and houses with shared walls, so if you live in a recently built home, you shouldn’t have a noise problem with your neighbours unless they are creating loud noise that is an environmental nuisance. Environmental nuisance created by noisy neighbours should be brought to the attention of the local authority who have powers to stop it. However, earlier houses and flats may have been created with separating walls that have little or no acoustic insulation so normal noise levels can more easily be heard from adjoining neighbours. Neighbours do not have to be loud to create a noise problem and it this type of normal noise the new Part E noise regulations seek to address. So noise from radios and speech at normal levels shouldn’t be heard and hopefully, this page will help you to soundproof any separating wall to reduce noise nuisance through a wall and improve the sound insulation to Part E standards.

Airborne noise is the most common problem experienced and effective sound proofing of the wall will help reduce the problem and give a better quality of life. Typical airborne noise is created by speech and music among and is quite different to impact noise. Impact noise is noise created by doors banging and footfalls on hard floors and is more difficult to address because this type of noise is structure borne and radiates through the fabric of the building. If impact noise is a problem, your neighbour could be unaware of it unless they can hear your doors as well. In these cases soft Acoustic Foam sealing tape such as our Acoustaseal applied to cupboard doors or on the doorstops of door frames will help reduce that type of impact noise. Alternatively, slow closing fittings can be adopted to stop doors from shutting too quickly and thus stopping the slamming noise fast closing doors otherwise make. Bare wood and laminate floors are another source of impact noise from footsteps along with furniture such as chairs being moved. The only real solution for this is to install carpet with a good quality underlay or for better results, an acoustic underlay such as our 10mm A10 but if it is noise from your neighbour, you will need their co-operation to do this, so invite them round for a cup of tea and amicably discuss the noise problem they are creating in a positive and friendly way.

Now we will move onto the two main solutions on how to sound proof a wall to reduce airborne noise nuisance. For best results, the floor and ceiling should be sound insulated first to reduce the possibility of flanking noise going around the party wall from beneath the floor and above ceilings. This is more of a problem if the floor and ceiling are supported by timber joists. With ceilings, if the room is on the top floor there should be fibreglass type loft insulation in place above the ceiling but if there is none then mineral fibre should be fitted to current thermal insulation requirements. If there is another habitable room above the ceiling it would be beneficial if 100mm of Acoustic Mineral Wool could be placed between the joists immediately adjacent to the separating wall and can be carried out by lifting a few floorboards. This will then act as a sound absorber that should reduce any flanking noise that would otherwise penetrate a ceiling. All ceilings should also be upgraded with an additional layer of 15mm high density Acoustic Plasterboard to give additional sound blocking performance before commencing with the soundproofing of party walls. With lathe and plaster ceilings, adding another layer of plasterboard screwed through to the supporting joists will ensure the plaster bonded to the lathes will remain secure and not risk falling on someone’s head when it ultimately becomes unstable.

Floor boards on the floor next to the wall to be treated also have to come up to allow access to the joists immediately adjacent to the party wall. Once lifted, as mentioned above, install 100mm of AMW100 between the joists butted to the wall if possible so that the slabs cover the space 1200mm from the wall. If the joists are parallel to the wall then simply infill the first set of two joists nearest to the wall then replace the flooring and screw down. Lastly, overlay the floor with a single layer of 2mm SBM5 Soundproofing Mat to add more mass. If you add several layers the additional mass of sound insulation become more effective at blocking flanking noise.

Now you can start work on the walls and for best results, our Studio Wall System should be used and will take up about 5.5 inches (140mm). The following link will give you more information on this. Studio Wall System There are also thinner solutions but it must be understood that thinner solutions are not as acoustically efficient so should only be used when it is not possible to install thicker, more efficient solutions that take up more space. To view the alternative options, click on the following link Soundproofing Walls. Soundproofing a wall that contains a chimney breast is never as good as it would be if the chimney breast was not there. If you have a chimney breast, before doing anything else to upgrade the soundproofing of the wall, insert a thin black bin bag filled with fibreglass loft insulation and stuff it into the fireplace then brick up the fireplace flush with the outside of the chimney breast. If it is an active fireplace this will obviously not be possible and the results of simply applying sound insulation to the walls alone will not be as efficient. Sound proofing of the wall can then commence also encapsulating the chimney breast.

the Thinner Soundproofing Options

The easiest method of sound insulating a wall is to use Acousticel M20AD. This is a recycled rubber product designed specifically to give a good level of sound reduction through any single skin wall with a minimum increase in wall thickness. M20AD is more effective when applied to single skin walls such as brick, lightweight blocks or stud partitions because these all allow unacceptable levels of noise through them more easily.

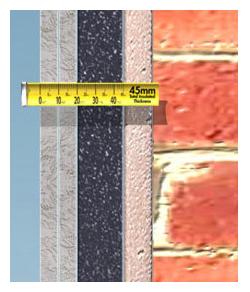

The M20AD insulation is easily cut and simply bonded to the wall with our Sta-Stuk aerosol contact adhesive with two layers of 15mm Acoustic Plasterboard glued on top giving a combined thickness of 2 inches (50mm). A link to more detailed application instructions can be found on the right hand side of the M20AD page.

This solution will significantly improve the sound insulation of any wall and if properly applied, should insulate the wall against normal every day noise such as speech and from televisions. Loud noise and low frequency noise are always the most difficult to soundproof and are usually impossible to eradicate completely, particularly at night.

However, using our sound insulation, these noises will be reduced in intensity. Independent tests have showed the M20AD solution would normally improve the insulation value of a single skin masonry wall from approx 45dB up to 56dB. This is a staggering 11dB reduction in noise through the wall

Acousticel M20AD is designed to reduce airborne noise through walls. Particularly effective on lightweight walls such as single skin masonry or stud partitions. M20AD is easy to install and cut when necessary with a jigsaw. No specialist knowledge is required and every order is supplied with full application instructions which can also be printed off from this web site. A thinner 10mm thick version of this material is also used as an isolation strip for studwork. Call for more details. If your noise nuisance is predominantly a low frequency noise problem then the thicker system described below for soundproofing a wall will give better results.

A thicker solution

Click here to download our brief PDF pictorial guide for soundproofing a wall with our core sound insulating products. A more traditional method of sound proofing a party wall is to install timber studs approx 25mm or further away from the existing wall. The voids between are infilled with SoundBlocker Quilt or Acoustic Mineral Wool of sufficient thickness followed by Resilient Bars that should be screwed across the uprights followed by two layers (30mm total) of Acoustic Plasterboard screwed to the bars. To enhance the sound reducing properties of this wall, SBM5 Sound Barrier Mat should be sandwiched between the two layers of plasterboard.

This method of soundproofing a wall is more efficient than the thinner M20AD solution and will perform better at reducing low frequency noise nuisance through walls but of course, will take up more space.

If space is not an issue and you are looking for the maximum reduction possible of noise nuisance through a wall, the above stud system can be further improved if a layer of our 20mm M20AD is glued to the plasterboard with another two layers of our Acoustic Plasterboard glued on top. This is the best system for all low frequency noise problems through party walls if you can afford to lose the additional space necessary.

Acoustic Mineral Wool

Acoustic Mineral Wool is a non-flammable product produced to a density that will give maximum sound absorption. This product is essential for application into the voids in stud wall partitions, ceiling and floor joists. Available in a variety of thicknesses, Acoustic Mineral Wool enhances the sound insulating performance of any structure in which it is installed and is particularly efficient when used as the acoustic infil for stud walls when constructed to soundproof a party wall. SoundBlocker Quilt performs 4 times better than normal mineral wool and is the preferred insulation used by installers as part of an overall soundproofing system.

Resilient Bars

Resilient Bars provide a flexible link between plasterboard and the timber stud to which it is applied. Resilient Bars are most useful when fixed across timber studs prior to Acoustic Plasterboard, which is screwed to the bars.

Soundproofing Mat SBM5

SBM5 Sound Barrier Mat is perhaps the most versatile product within our range. This mineral loaded recycled product has a high mass for minimum thickness which is similar to lead. SBM5 can be used to substantially enhance the sound insulation qualities of plasterboard when decoupling the layers. This 'deadsheet' is an excellent anti-drumming material and is also used to improve the sound insulation factor of separating floors.

Written by Stephen Young

© Sound Service (Oxford) Ltd 2003